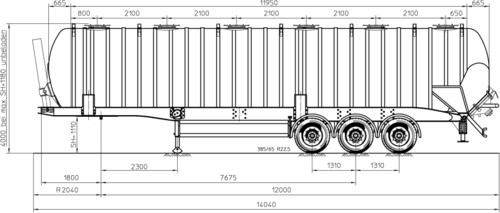

Tipping silo semi-trailer KIP 63.3 S+D ADR

Volume approx. 63 m³

Product information

| Tank | Self-supporting pressure vessel made of special aluminium alloy X-TRAL EN AW5088 H 111 Elongal AW 5186 H 111, Alutrans A Plus AW 5182 H 111 or of the same value with vacuum stabilising rings. |

| Compartments | 1 |

| Manholes | 6 x DN 450 |

| Operating parameter | Test pressure: 2,65 bar Operating pressure: -0,5 to 2 bar Operating temperature: -40°C / + 80°C |

| Discharge | Pneumatic, with electro-polished, stainless steel flanged discharge bowl DN 800. Electro-polished stainless steel slit aeration or pad aeration insert. Aeration systems are exchangeable. Material discharge DN 150 with butterfly valve, reduced to DN 100 with Rosista coupling and blank cap. |

| Airline | Common aluminium airline 3”. 4” electro-polished stainless steel manifold pre-fitted for later fitment of an 5 micron filter. Approval by regulation of DOW-Chemical. Aluminium top airline 2”. |

| Tipping equipment | Hydraulic ram in front of tank. 2 mechanical safety supporting legs at rear of chassis. |

| Chassis | Bolted and welded construction made of special aluminium alloy. |

| Catwalk | Aluminium catwalk, 400 mm wide, handrail and ladder made of electro-polished stainless steel. |

| Running gear | 3 x 9 t disc brake assembly on FFB aluminium hanger brackets, low-maintenance axles and air supension. |

| Tyres | 6 x 385/65 R 22.5 on forged and dull finished aluminium rims (Alcoa). |

| Brakes | ABS/EBS brake system in accordance with EU regulations. |

| General information | 2 fold PVC hose carriers, PVC tool box, 2 x 12 t landing gear, lighting and underride protection in accordance with EU regulations. |

| Painting | 2 tone acrylic paint without lettering. |

| Weights | Total weight: 34,000 kg Tare weight: approx. 7,700 kg Payload: approx. 26,300 kg |

28.02.2014